GENERAL

|

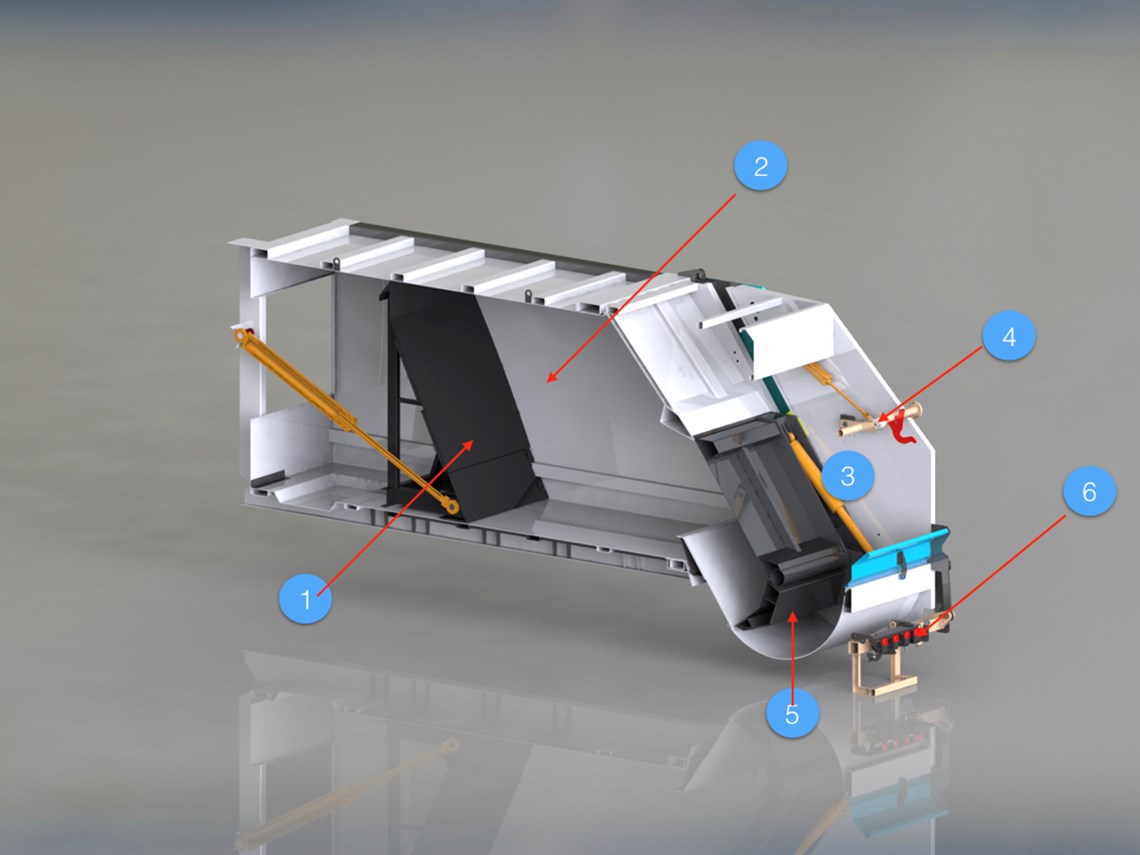

1 |

DISCHARGE PLATE |

|

2 |

BODY |

|

3 |

TAILGATE |

|

4 |

CONTAINER COVER OPENER |

|

5 |

COMPACTION PLATE |

|

6 |

CONTAINER HOLDING ARM |

|

7 |

FOOTBOARD |

Hydraulic garbage trucks are home waste collecting and transporting vehicles which are loaded either by hand or by container.

In garbage trucks produced by HİDRO-MAK, body, discharge plate, hopper, compaction plate and hydraulic-pneumatic-electric diagrams are produced as a whole.

BODY : This is the part where compacted waste is stored. Body is produced by high mechanical strength steel and NPU. After the welding phase, the superstructure is cleaned from rust, oil and other mini particles for painting phase. Inside the body, discharge plate is located. With the help of the hydraulic cylinder, 6..26 m3 home waste is compacted depending on the capacity. (2)

DISCHARGE PLATE : is located inside the body. Discharge plate moves on polyamide plates. After welding phase, it is painted. The movement of discharge plate is enabled by telescopic cylinder. (1)

TAILGATE : Tailgate is located on the back of the body and connected to the body with 2 hinges . When necessary, the tailgate opens and discharges the waste inside. Tailgate is produced from high strength steel. Tailgate is a whole with hopper and compaction plate. With the help of the guidance mechanism, compaction plate opens and operates. The hopper is used for loading waste. To prevent the tailgate from accidental opening, it is connected to the body with 2 hooks. The tailgate opens with the help of 2 cylinders. When it is necessary to go into the body for cleaning or maintenance, the support arm must be fastened. (3)

COMPACTION PLATE and POLYAMIDE : Compaction plate is made up of high strength steel. Connection elements are made up of special quality of steel. Polyamide components are inside the tailgate. (5)

Compaction plate moves on inclined surface. Compaction plate compacts the collected waste in the hopper into the body.

HOPPER : Hopper is the back of the tailgate in which waste is loaded either by hand or by container. The hopper capacity is about 0.8...2.0 m3.

COMPACTION CYCLE : Compaction plate moves initially backward then downward. At this point, the compaction plate compacts the waste in the hopper. While the compaction plate moves up, it also sweeps and compacts all the waste into the body. While compacting the waste into the body, the discharge plate is also pushed towards the cabin of the truck. When the compaction plate reaches it’s final point the compaction cycle is over. During this cycle, the hydraulic pump provides the necessary pressure.

CONTAINER HOLDING ARMS : Container holding arms are used when waste loading is to made automatically. The arms to hold the container up are operated by two cylinders. This mechanism is controlled by an arm controlled valve and speed is adjustable. (6)

LOADING HEIGHT: When the body is empty and ready for loading, the loading height is designed so that the operator can not touch the compaction plate.

FOOTBOARD : Footboard is the fixed or movable location where the operators will stand while the truck is moving. (7)

DISCAHRGE SYSTEM : The system that discharges the waste from the body.

DISCHARGE TIME : After completing the compaction process (body is full), discharge time starts when the tailgate opens and continues until it closes again after discharging the waste.

EMERGENCY STOP BUTON : Emergency stop button (red color) is used in emergencies that may happen during the action of compaction plate. Emergency plate is located on both sides of the tailgate.

RESCUE BUTTON : Rescue button is used after the use of emergency button. (yellow color). When the rescue button is triggered, the compaction system moves upwards immediately.After pressing this button, in order to start the vehicle again the restart button in the driver cabin should be pressed.

Garbage Truck Bodies (Rear Loaded Refuse Colletor is working Hydraulic, Electrical and Pnomatic System. This Table explain the problems and troubleshooting.

25 July 2016

Garbage Compactors have a lot of moving parts. As a result of this, Garbage Body and parts need a maintenance regularly. This article about maintenance point and oil specification.

04 May 2016

Hydraulic Compacting Rear Loaded Garbage Body Parts

03 May 2016